Delivery Optimization

in Premium Appliance Retail

Introduction

A high level of service often becomes crucial for a business operating with premium goods and customers. A high-income audience has high demands — both for the quality and characteristics of products, as well as for the interaction between the client and the seller. In particular, these customers value an individual approach, exclusivity, and a high quality of pre-sales and after-sales service.

Reading this case, you'll learn how transportation optimization helps premium retailers cope with the excessive operational load and provide a level of service that meets their premium audience’s expectations.

Client profile

Description:

a European premium appliance retailer

Established:

1992

Stores:

80+

Brands:

890+

Situation

After the pandemic started, the daily reality of the retail industry changed a lot. In the Spring of 2020, the number of online orders across Europe increased several times in a couple of months. Thus, many large retailers had to endure a crash in their logistics systems.

In April 2020, many delivery departments could barely cope with the new workload volume. We have already spoken about this regarding our cooperation with a large online retailer.

The situation on the market turned out to be a serious challenge for the company for 2 reasons.

Reason 1. People who buy premium appliances are a relatively small audience and could be extremely sensitive to the service level.

The target audience of such brands as Smeg and Kuppersbusch is mostly upper-middle-income clients. Meanwhile, in 2020, the average income of the population of Eastern Europe has fallen by a record 8%. Even entrepreneurs and the middle class suffered enormous financial losses.

Therefore, it would be reckless to expect a significant increase in new customers, even considering the growing volume of online orders.

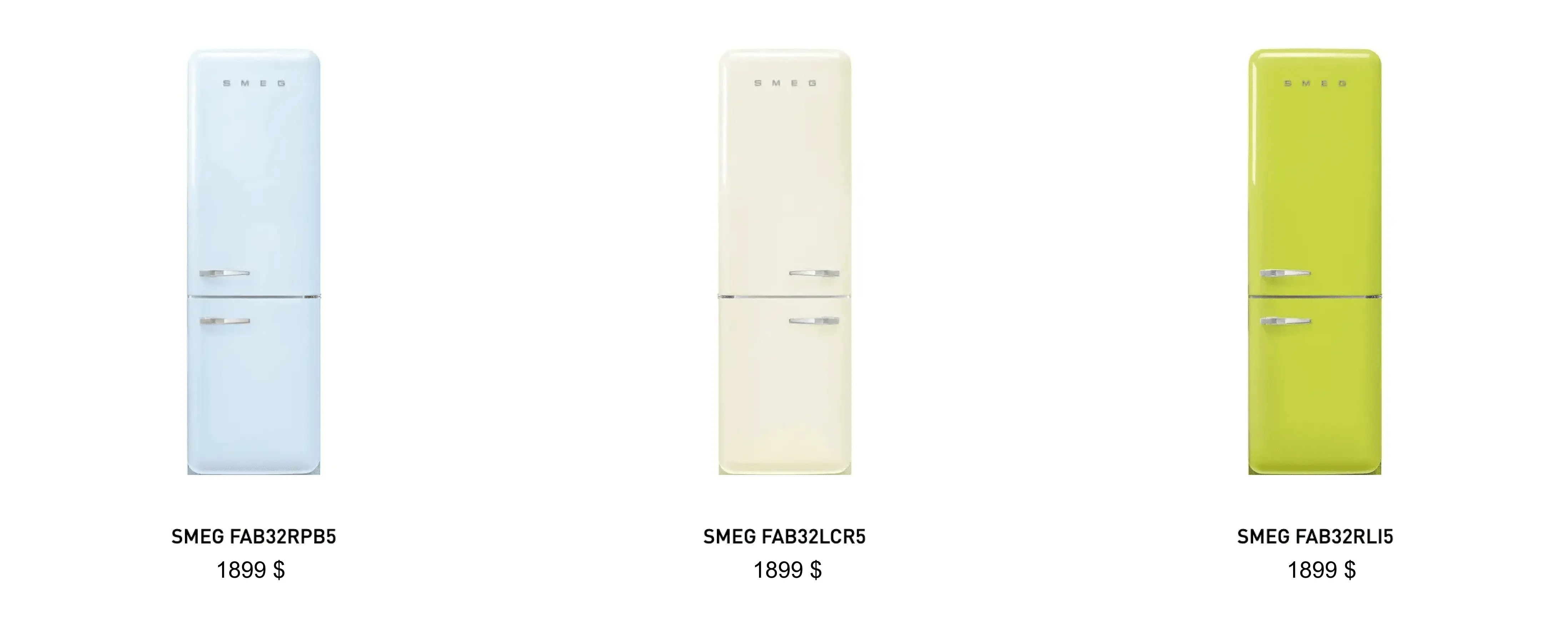

In such circumstances, it would be rational to bet on maintaining customer loyalty. It means your service level should be better than ever. After all, the clients who are able to buy a fridge for $1899 pay close attention to the service quality. That's why no mistakes are allowed.

Reason 2. Route planning was carried out entirely manually.

The need for business process automation has been apparent for a long time, but the lockdown made it obvious and urgent. In the new reality, it would be enormously difficult to maintain the usual level of service without automation — and even more difficult to improve it.

When the bulk of sales moved online, the volume of daily work associated with delivery increased several times. At the same time, at the company, only one logistician was engaged in building routes. Manual routing took at least 2-3 hours, and the employee had to work overtime regularly to get his job done.

This situation was doubly harmful to the company:

The logistician has unwittingly become a bottleneck. Without having this particular employee at the workplace for any reason, the company’s business processes could simply stop entirely.

A huge volume of monotonous work, irregular workdays, and a disproportionally large level of responsibility had a negative impact on the productivity and well-being of the employee.

These two factors endangered the delivery speed. Thus, it became harder to provide the service level agreement (SLA), which was crucial considering high demands of the premium audience.

Challenge

Searching for a technology partner, the customer decided to opt for Veeroute. In comparison to other contenders, the Veeroute team showed stronger motivation, greater enthusiasm, and a client-oriented approach.

Before integration, the key challenges were set:

Automate and optimize the routes considering the increase in the number of orders

Keep the service quality at a high level and avoid reducing the SLA

Solution

Joint work on the project began in April 2021. The Veeroute optimizer was integrated into the CRM system installed in the customer's IT infrastructure.

During the testing, the geography was limited to two regions of population of 18 million people in total. The average volume of delivery among their territory is 1,000 points per day.

Results

The first results of integration were summed up in Autumn 2021. The following results were achieved:

Manual routing was replaced with automatic routing. Thus, the route building time was reduced from 2-3 hours to 40 minutes.

The customer managed to cope with the increased number of orders and maintained a high service level.

The company has evaluated the cooperation with Veeroute as a positive experience. In the future, the customer is planning to scale the joint solution to the other regions of the delivery zone.