Leveling Up Service Quality with Veeroute Automated Planning

Introduction

The “service level” of a service company is a combination of their engineer’s competency, accuracy, and, most importantly, user experience. Clients expect a prompt reaction to their requests, as well as clear and simple processing. To fulfill that each time, the service company performs a complex cycle:

Analyzing all the incoming requests

Comparing them with the existing ones

Considering the locations of the engineers and the client

Choosing an acceptable engineer

Suggesting the best time slot for the visit

If processing is manual, then, obviously, it takes plenty of time. But have you ever thought about automation?

Learn how the Veeroute optimizer automates the processing of service requests, improves the level of service, and leads to more benefits.

Client profile

Description:

Security systems provider

Established:

1994

Geography:

23+ cities in Europe, including Germany and Italy

A security system’s configuration is complex; it includes dozens of sensors that track movement, smoke, leaks, electrical health, etc. In addition, sensor monitoring and instant alarm responses protect the premises from burglaries, attacks, fire, or gas leakage.

The company serves more than 75,000 clients and employs several thousand specialists who are engaged in:

Designing and installing security systems

24/7 monitoring and alarm response

Providing service and customer support

Challenge

A problem the company met was the flipside of business growth: the more requests they received, the more difficult it became to process them without reducing the quality of their service.

The support service processes 200-300 requests daily. Before the automation, this work was implemented in 3 stages:

A client talked to a contact center operator over the phone, who clarified requests, and put them through to a logistics dispatcher.

A contact center operator talked to clients over the phone, clarified requests, and put them through to a logistics dispatcher.

The logistic dispatcher would clarify the request details and would manually plan the date and the time that the service engineer would visit.

As the number of requests increased, two dangerous factors were revealed:

Service request processing is routine work.

When more identical actions are performed, there’s a higher chance of making a mistake.

The more requests there are, the higher the queue’s waiting time will be.

If a service engineer visit is not scheduled during the first call, the approval process may take a long time.

As a result, the perceived service quality was at risk. Even though service engineers were performing their work at a high level, the client might remain dissatisfied.

The company’s management started to search for a digital solution. This decision came naturally because request processing consisted of simple and uniform actions that could be easily automated.

Two tasks were formulated for the required instrument:

Minimize human involvement in routine operations.

Achieve a service level that allows clients’ issues to be solved with just one request.

Solution

Veeroute’s collaboration began with the integration of a standard optimizer. It was used to plan the routes of service engineers.

In the implementation process, a “checkerboard” was created. It is an additional tool that allows the company to plan the service engineer visit in just a couple of clicks.

What is the checkerboard?

The “checkerboard” is a simple interface similar to a timetable; the columns are the days of the week, and the rows are time intervals. The cells at the intersection are highlighted in different colors, which indicate whether a certain time slot is free or reserved.

| Date/Time | Sun | Mon | Tue | Wed | Thu | Fri | Sat |

|---|---|---|---|---|---|---|---|

| 9 am - 12 pm | 10 000 | 2 210 | 1 500 | 200 | 619 | 1 120 | 580 |

| 12 pm - 3 pm | 10 000 | 1400 | 670 | 470 | 50 | 710 | 580 |

| 3 pm - 6 pm | 10 000 | 150 | 950 | 619 | 650 | 720 | 470 |

| 6 pm - 8 pm | 10 000 | 10 000 | 10 000 | 10 000 | 10 000 | 10 000 | 10 000 |

Although it’s visually simple, the checkerboard relies on complex mathematical algorithms that take into account many parameters — such as the planned type of work, the client type, the location of the facility, and the engineer.

Due to Veeroute's high performance, the checkerboard works quickly and copes well with dynamic planning. An operator receives information about free slots within a few seconds and can plan a visit in a couple of clicks.

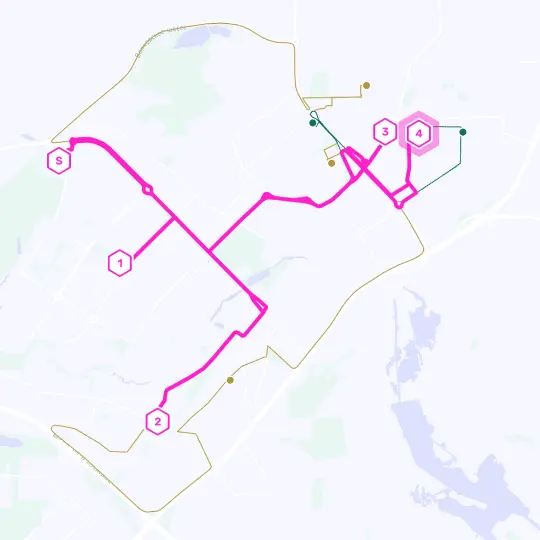

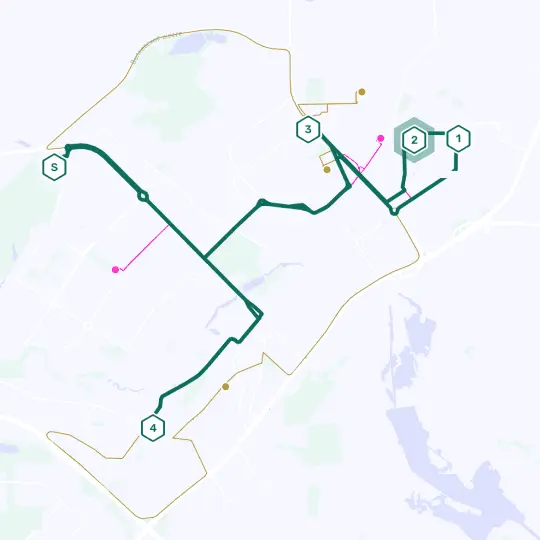

Compared to manual planning, the checkerboard is much more efficient at distributing the requests on the map among available performers:

The engineer's route is built within a particular area so that they spend a minimum of time moving between the objects.

The route starts from the object that’s as close to the engineer's residence as possible.

Most requests need a standard service that takes no more than 30 minutes. The checkerboard interface takes this into account and optimizes the schedule accordingly. With its implementation,the daily number of completed requests has increased by more than 100%.

Results

Veeroute’s optimizer, in conjunction with the checkerboard, has shown high efficiency in practice. The company has achieved the following results:

Routine work has been reduced, lowering dispatchers’ stress.

With routine operation automation, it was possible to level and optimize the workload of the contact center operators.

Visit scheduling time has been reduced.

Before the introduction of automation, it took 4+ calls to agree on a service engineer visit time. Now, it only takes 7 seconds.

Fuel and lubricant expenses have been reduced.

After the optimization integration, fuel and lubricant costs have decreased.

Service engineers' work efficiency has been increased by 50%.

With manual planning, one engineer could cope with 5-6 requests per day. After the checkerboard implementation, this number has grown to 13. At the same time, the company was able to maintain its service level, and the employee’s working conditions remained as high as before.

The checkerboard’s simplicity has helped to introduce self-scheduling algorithms.

Upon receiving an automatic mailing about the upcoming service period, a client can follow the link from a letter or an SMS and independently schedule a visit from a service engineer.

I think that unique algorithms on which Veeroute solutions are built can be used in any business. They easily automate the scheduling process and effectively distribute resources, taking into account the location, type of work, available engineers, and more. This distribution will be the most cost-effective method, and the costs of automation will pay off quickly!

CIO of security systems provider